In response to an article for TransportMedia, we were asked why companies would choose a connectivity solution for their trailers and containers AFTER purchasing or leasing them. After all, there are several trailer manufacturers that build in tracking capabilities during production. A good question, indeed. However, the answer lies mainly with the principle of the cobbler and his last.

Key advantage of a non-branded strategy for trailer and container tracking: avoiding scattered data.

It is a good reflex to ask the question why you would opt for connectivity solutions from a third party (such as Suivo) rather than the solution that container and trailer manufacturers provide themselves. After all, there are already many manufacturers today – whether trailers or tools – that incorporate proprietary technologies to provide traceability.

There is nothing wrong with those solutions, per se; they usually do what they are designed to do. The point is that each brand designed its own platform or software to effectively make use of track & trace functionalities.

You then have to log in for each brand and users then have to get to know and use different platforms. Moreover, all the data is in different places. You don’t have an overall view.

It is therefore a smart idea to adopt a non-brand-dependent strategy and opt for an open platform.

Thanks to an open platform you can centralize all data, regardless of which suppliers or brands you use. This centralization of data provides a complete overview and also makes it much easier to connect data with each other. This enables you to see ‘the bigger picture’, to gain insights faster and to make smart decisions.

The Suivo IoT platform is such an open platform. It enables you to read and collect all available data from the CAN bus of your trailers in one central place. Relevant data such as weight, loading info, tire pressure, etc. can be seen at a glance, during or not during driving time.

Even if there is no data available from the CAN bus, it is still possible to locate your trailers.

A few steps ahead: reduce the threshold to smart asset management and driver identification.

On top of that, an ‘aftermarket’ solution offers additional features (if desired) that are not feasible for trailer manufacturers. By using a Hydrogen tag for example, you also know which trailer is linked to which tractor and even driver identification becomes possible. If you use Oxygen tags (Oxygen = a Suivo product family that mainly includes small and budget-friendly tags) for tagging other assets, you will also know exactly which materials and tools are in your containers or on your trailers.

Keeping it simple: implementation is a picknick.

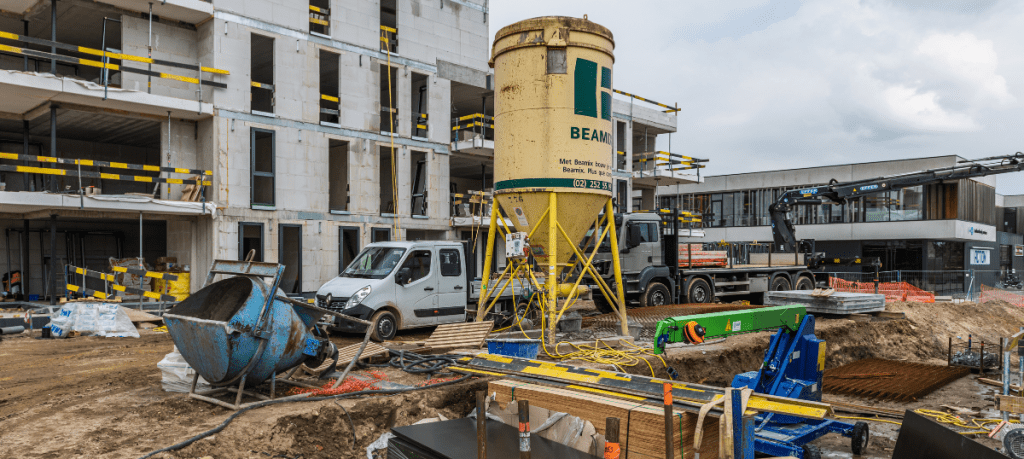

An additional advantage is the limited installation time. These solutions are very easy and quick to deploy. After following a short hands-on workshop, your own employees will be able to install the solution themselves. It doesn’t get any more ‘plug & play’ than that. In one hour the installation is done!

Flexible with range, frequency and communication protocols.

The need for accuracy of location determination, may well vary.

The big advantage of the open platform is its flexible use. For example, when you have been using your trailers for a while and you notice that you don’t need such precision, then we can just reconfigure it. Perhaps you then choose less precision in combination with less power consumption (or vice versa).

Of course, it is also conceivable that you will not always want to localize trailers to the same extent.

For a stationary container or trailer it is often sufficient to know its location only once every 24 hours. Is the trailer in motion? Then you may want to track it in real time. These are things that we can all customize to suit your needs.

There are therefore numerous possibilities in terms of range, frequency and communication protocols (GPRS, 2G, 4G, LTE-M, LPWAN, Sigfox, LoRa(WAN), RFID, NFC, QR, Astrid, WiFi, etc.). By cleverly combining these in function of your goal or application, you always remain very flexible. Moreover, the solutions from the different product families can be combined very well. You choose the modules that suit your needs.

Reporting and Dashboards: the bridge between your data and smart decisions

The Suivo platform allows you to centralize a lot of data, not only the data captured by Suivo tags and trackers. The possibilities go much further.

There are many possible integrations with suppliers of materials or tools, but also with ERP systems, personnel tools and software from inspection authorities etc. Such an open platform with so many integration possibilities creates real added value. You can imagine what a data enrichment it means to link these different things.

In addition, everything is displayed in clear dashboards. So not only do you optimize your workflows, but you also waste less time on administrative tasks. Tailor made dashboards visualize your most important or relevant data. You can select the widgets that apply to your organization.

These dashboards are the bridge between your data and smart decisions.

More than easy planning of maintenance and inspections

Thanks to the links with parties that perform inspections and tests, you know for each asset (or trailer in this case) in what ‘state’ it is.

For example:

- “approved”,

- “needs to be inspected”,

- “in maintenance”,

- “damaged”, …

This makes it a lot easier to plan and it guarantees the safety of your employees who have to handle the materials / assets. So it is effectively clear when trailers must be inspected or repaired or when they are available. The entire workflow and planning is transparent, enabling you to make substantial optimizations.

Impact on your purchasing policy

There are more examples of how data can help you on your way to more efficient processes.

Some examples:

- Suppose you notice that x number of trailers have been stationary for more than 60 days, but you rent trailers from third parties in the meantime, then this is very useful information for the purchasing policy, leasing / rental costs and planning.

- The fleet manager who has been able to deduce from the data that tires are being driven for too long with too low a pressure, can avoid premature wear by adjusting the processes where possible.

The optimization possibilities are endless when you discover the power of power BI.

Stay tuned!

Suivo will soon be launching a new 5G-ready Trailer Unit. What’s special about it?

- ultra-simple installation

- best-in-class autonomy

- the connection with the Suivo IoT Cloud Platform offers the possibility to further enrich your data by expanding with other (Suivo) tags and sensors.